GATES G-FORCE REDLINE 47R4368 – Drive Belt for Arctic Cat Snowmobile

Original price was: 210,47 €.SALE 186,00 €Current price is: 186,00 €. 186,00 €

incl. 20% VAT plus shipping costs

GATES G-Force RedLine CVT Belt 47R4368 – Arctic Cat / Textron Snowmobiles

Replaces OEM # 0627-112, 0627-110

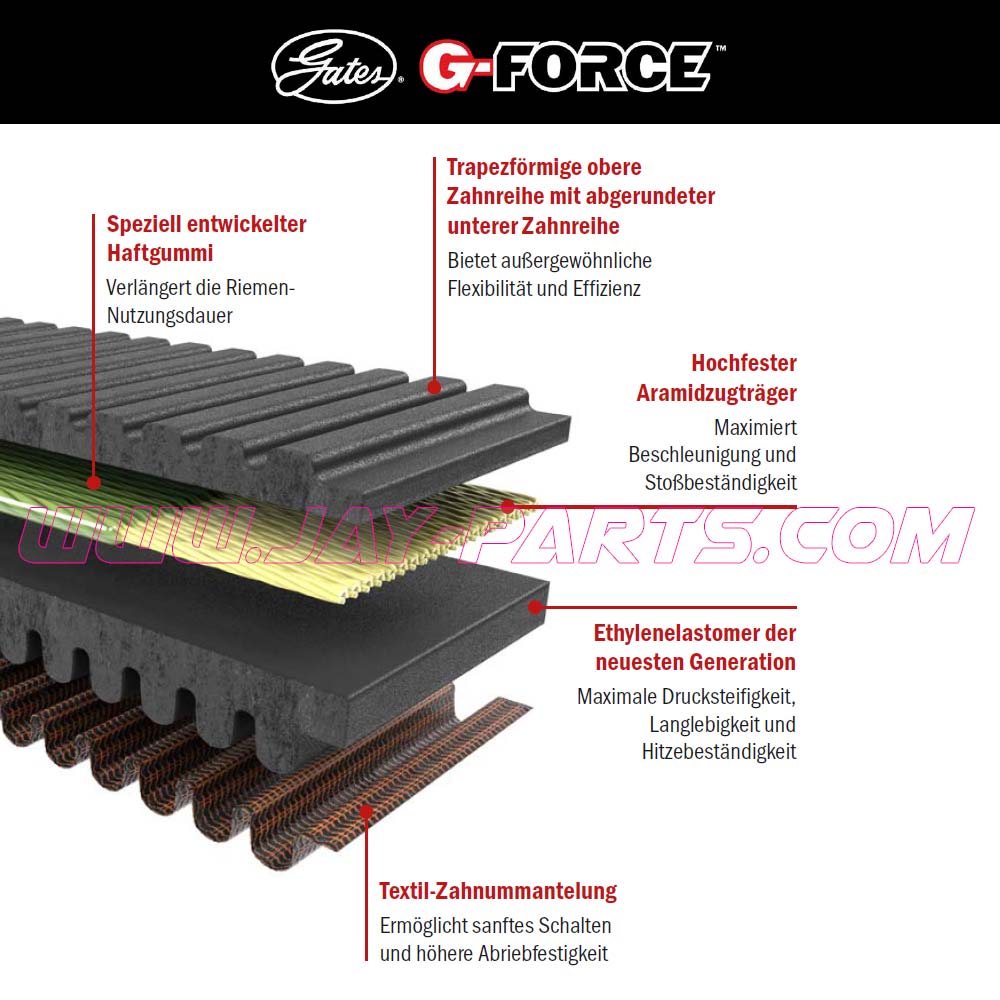

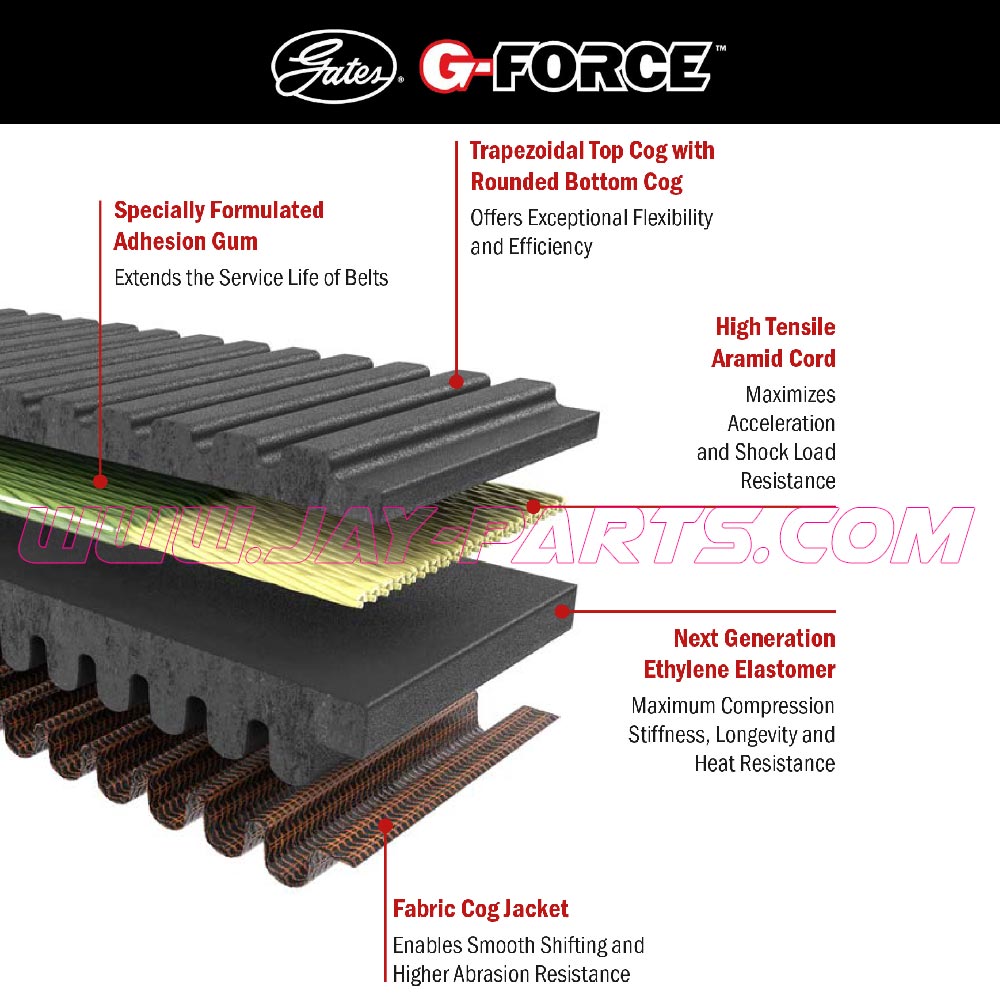

- high Tensile Aramid Cord

- next generation Ethylene Elastomer

- from temperatures up to 338°F (170°C) without power loss

- maximum heat resistance

- higher peak torque capacity

- high-performance power transmission belt

- off-road performance engineered

- Made in USA

Availability : in stock

In stock (can be backordered)

GATES G-Force RedLine CVT Belt 47R4368 for Arctic Cat Motorschlitten XF7000, XF9000, ZR9000

The RedLine ™ power transmission belts from GATES are made of the unique, patented EE (ethylene elastomer) compound, which offers significantly higher transverse stiffness and heat resistance than any other material composition.

The high-performance vehicles of today place greater power transmission demands on belt technology more than ever before. Rapid acceleration and high variable torque loads generate tremendous compression and excessive heat which degrade belt performance.

THE G-FORCE REDLINE ™ DEFIES THE HEAT LIKE NO OTHER BELT FOR VARIOMATIC TRANSMISSIONS.

This results in exceptional heat resistance, durability and load capacity under extreme driving conditions. The result is a drive belt that can withstand extreme friction , high compression forces and excessive heat better when your CVT system is exposed to high frequent load changes and heavy loads. Delivers 75% greater dynamic axial stiffness on average, up to 50% lower speed losses and better recovery from temperatures up to 338°F (170°C) without power loss

RACE-PROVEN INNOVATION

The Gates G-Force RedLine™ CVT belt was developed in collaboration with championship-winning racers using the most advanced materials and construction, then tested on top platforms in the most extreme Southwest desert race events also in mountains and on race tracks.

WHY G-FORCE REDLINE?

The most advanced combination of materials and technology on the market today:

- Optimized, patented EE compound

- maximizes axial stiffness and heat resistance

- run at higher continuous torques or loads

- less "heat fade" and less speed loss

- geringeren Drehzahlverlust

- delivers 75% greater dynamic axial stiffness on average

- up to 50% lower speed losses and better recovery

- from temperatures up to 338°F (170°C) without power loss

- extremely fatigue-resistant,

Made in USA

ATTENTION

Not only correct assembly but also correct retraction of the belt is extremely important for the service life of every belt!

Please note the vehicle model list!

Installation

CVT-BELT INSTALLATION & BREAK IT IN

Not only correct assembly but also correct retraction of the belt is extremely important for the service life of every belt!

NEW BELT INSTALLATION

Choosing the right belt for your vehicle is critical for optimum performance. Please use the JAY PARTS drive belt finder. To ensure optimal operation of newly installed belts, the CVT sheaves must be cleaned of all old belt residue, dirt, debris, and oils. If any particles remain, belt slip and a noticeable drop in vehicle performance can occur

At JAY PARTS there is a 3D-Softflex – Non-Woven Abrasives-Pad FREE of charge with every GATES G-FORCE REDLINE CVT drive belt! Remove old belt residue, dirt, debris, and oils from the clutch sheaves with 3D-Softflex non-woven abrasives pad and isopropanol alcohol or acetone poured or sprayed on a rag.

ATTENTION: Do not spray onto the clutches and do not use brake cleaner.

- Make sure the vehicle is in park or neutral and the engine is off. Remove the cover of the clutch.

- If possible, blow out the clutches and all inlet and outlet openings in the clutch box with compressed air to remove dust, dirt and debris. If the previous belt broke, remove all the debris and cord if any are left in the primary or secondary clutches. Completely clear all inlets and outlets, especially the variomatic outlet, of any belt residue.

- If possible, check for correct alignment by checking the center-to-center distance between the primary and secondary clutch, see the vehicle manufacturer’s manual.

- Clean the clutch sheaves with the 3D-Softflex Non-Woven Abrasives-Pad and wipe them clean with isopropanol alcohol or acetone poured or sprayed on a rag – do not spray onto the clutches. Repeat this procedure until the sheaves surfaces are completely cleaned and dry. Do NOT use brake cleaner!

This removes the old belt residue and oils which can cause the new belt to slip. - Open the secondary clutch with suitable tools as recommended by the OEM. Install the new belt so the lettering can be read right side up. Although G-Force belts are not directionally biased, it is recommended to install them with the label lettering facing toward the user to keep belt reinstallation consistent. DO NOT FIT THE NEW BELT WITH A LEVER. (Note: When reinstalling the belt, always install it in the previous orientation to keep the belt wear profile aligned with the sheaves profile.)

- After installation, release the tension on the secondary clutch. Turn the secondary clutch anticlockwise until the belt reaches its initial position.

- Remove the tool that may have been placed on the vehicle.

- Mount the clutch cover on vehicles with a vario shaft mounted in the cover. If the vario shaft isn’t mounted in the cover, start unit up in park and let it idle for 30 seconds. Turn off the engine and replace the clutch cover. Give a quick throttle.

CAUTION: DO NOT reach into the clutch (rotating parts)

If the belt doesn’t come to rest and stop spinning in Park and the idle has dropped to normal warm engine rpm, check your system for alignment and proper operation of the variomatic. On snowmobiles you may need to adjust your deflection several times. - See the vehicle Owner’s Manual for proper alignment and center-to-center distances of the clutch system.

- When the belt stops in park and neutral mode, replace the cover and proceed to break-in process of a new belt.

PERFORM A HEAT CYLE – DON’T BREAK IT. BREAK IT IN.

If you take the time to break in a new belt gently and carefully, the belt will run smoother and you will have maximum life and performance. Follow the next HEAT CYCLES:

- Drive the unit in two wheel high for 20 minutes between 25-45 mph (40-72 km/h) avoiding hard accelerations and hills. Flat terrain works best. Vary vehicle speed and engine rpm to cycle the belt in the normal operating range, but not more than ¾ of the maximum force during retraction. In extremely cold weather, it is advisable to extend the break-in time by 5-10 minutes to allow the belt to warm up optimally.

- After 20 minutes of driving, let the unit cool down for 30 minutes with the motor off.

- Repeat the HEAT CYCLE for a second time. Let the belt cool down again for 30 minutes.

- Repeat the HEAT CYCLE for a third time. Let the belt cool down again for 30 minutes and you have a well broken in belt.

Troubleshoot

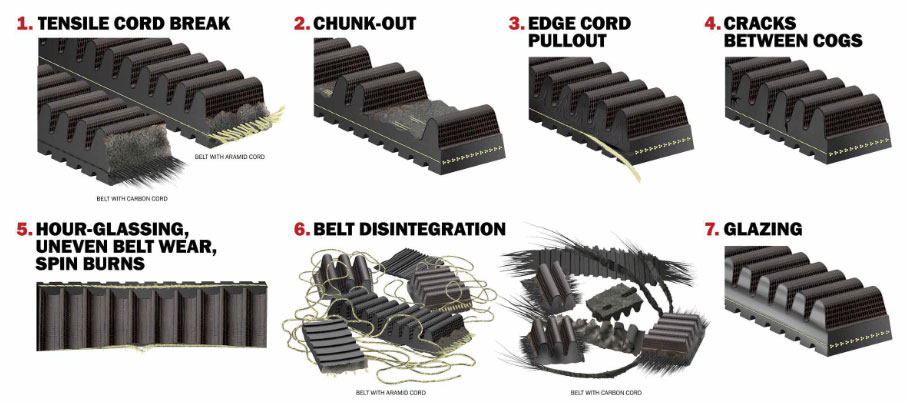

GATES G-FORCE POWERSPORT BELT FAILURE ANALYSIS – IDENTIFY AND TROUBLESHOOT CVT DRIVE ISSUES

SYMTOM | POTENTIAL COUSES | RECOMMENDATIONS ⇒ READ FULL DOCUMENT FROM GATES (pdf)

| KAT/CAT | Marke/Brand | Jahr/Year | Modell/Model |

|---|---|---|---|

| KAT/CAT | Marke/Brand | Jahr/Year | Modell/Model |

| Belt | Arctic Cat | 2018 | XF7000 Crosstour |

| Belt | Arctic Cat | 2018 | XF7000 Crosstrek |

| Belt | Arctic Cat | 2018 | XF9000 Crosstour |

| Belt | Arctic Cat | 2018 | XF9000 Crosstrek |

| Belt | Arctic Cat | 2018 - 2019 | M9000 |

| Belt | Arctic Cat | 2018 - 2019 | Pantera 7000 |

| Belt | Arctic Cat | 2018 - 2019 | XF9000 |

| Belt | Arctic Cat | 2018 - 2019 | ZR7000 |

| Belt | Arctic Cat | 2018 - 2021 | ZR9000 |

Add a review

Produktanfrage / Request to product: GATES G-FORCE REDLINE 47R4368 - Drive Belt for Arctic Cat Snowmobile

EU product safety

Manufacturer information

MANUFACTURER

Gates Industrial Corporation plc

1144 Fifteenth St., Suite 1400, Denver, Colorado 80202, USA

compliance[at]gates.com

AUTHORIZED REPRESENTATIVE EU

Gates Industrial Europe Sàrl

33, rue de Gasperich, L-5826 Hesperange, Luxembourg

gatesar[at]gates.com

DISTRIBUTOR

JAY PARTS GmbH

Lothringenstrasse 6/20, 4501 Neuhofen an der Krems, Austria

info[at]jay-parts.com

Reviews

There are no reviews yet.